Понимание важности сосредоточения усилий на всей системе управления запасами со статистической точки зрения

Петр Пруша,

доктор, научный руководитель,

Купцова Анастасия Александровна,

докторант.

Пардубицкий университет, Чехия.

The statistical method for understanding the importance of inventory control

Petr Průša,

Ph.D.University of Pardubice. Jan Perner Transport Faculty. Department of Transport Management, Marketing and Logistics,

Anastasiia Kuptcova,

doc. Ing.

The article deals with the application of the liner regression analysis: dependent variable is order quality. This report briefly describes the factors influence on the dependent variable as ordering costs, transport cost and inventory cost. It is then applied linear regression analysis in the statistical package for the social sciences. Article defines tightly interrelated factor cost to order quality in the order fulfillment process. Susceptibility factor it would be performed.

Keywords: Logistics cost, EOQ, Linear regression analysis, inventory management.

1. Introduction.

Each firm and enterprises throughout the commercial value must identify and understand steps for the regulation of order delivery. It means to have requirements review of economic efficiency. Each industry is linked to some type of factors that affects the increase the efficiency in core operation. In this article factors would be associated with logistical cost. The logistical costs represent large share of the budget of Industry Company. Particular attention is directed to the study Economic order quantity that involved the economic value in the linkage between planned activities such as production planning, demand forecasting and the expected outcomes. Practical approach to the case study turns with respect to the linear regression analysis. The linear regression analysis illustrates parameters of logistics costs to order. The goal of article is to verify how strong that dependent is.

2. Logistics

«The main tasks of logistic management are to execute the orders and to fulfill the requirements of consumer and companies at lowest cost with adequate quality »1.

Logistics is multidimensional way including value added activity. Added-value approach is commonly defined as getting a benefit via reduced costs. The structure of value added activity was mainly based on trade rules. Logistics cost is sensitive side in logistics service providing. Predicting of production capacity and logistics charges can be problematic. It underlines that strategic cost management analysis have to be implemented.

The strategic dimension of logistics can be considered through improved material requirements planning. Today it refers to the understanding of affecting power of Factors Influencing and to the applying set of operation for minimization production expenses. For optimization of material demand and supply will be most useful to provide case study related to order quantity, quality, delivery, policies warehouse and cost fulfillment.

2.1. Logistics cost

Logistics is a key process which combines customer service and production operation. Logistics has to achieve two business goals of customer satisfaction and cost - cutting. Logistics total cost reduction is depends on the reduction cost on the every stage of transportation services: inventory operation, procurement procedures, freight delivery service, working with suppliers, IT transaction and other logistics option [2, 3, 4].

Logistics cost includes:

• cost of storage and warehouse activities;

• cost of delivery activities;

• cost of investment policies;

• cost of logistics service provider;

• cost of information technologies and telecommunication systems;

• cost of distribution operation;

• cost Risk of Logistics; [1-8]

Cost is the most important criteria in the selection of configuration logistical cycle. Operating strategies should make resource-saving best practices. This practice takes care of material handling operation. All operative decision depends on the answers to one of main question: How to keep costs down in a filling process?

The emergence of advantage in modern business is based upon regular monitoring in calculation of logistics cost. Logistics cost can be minimalized by effective management system [4]. Build to order supply chain is to apply the demand solution within management operation functions— such as planning vendor, transportation planning, distribution requirements planning; manufacturing resource planning— must be based on economic ordering quantity.

2.2. Economic Ordering Quantity (EOQ)

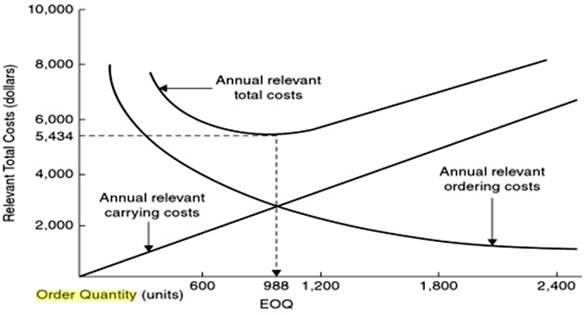

Negotiation model for supply management is order quantity. Economic Ordering Quantity (EOQ) is the financial formula calculated ordering quantity, based on the optimal balance of costs between inventory cost and order cost. EOQ is used to measure the optimal number of units of the goods to order so that to minimize the total cost associated with the procurement, transportation and store of the product [10, 11, 12]. EOQ is the oldest production scheduling methods that induces demand solution. Variation of the cost is demonstrated on the graph [13].

Figure 1. Economic Order Quantity Decision model. Source: [13].

A demand condition is the fixed cost to locate and stowage for the year. Number of times order will also influence the total construction cost [10, 11, 12]. Generally, EOQ is considered by the cost factors in three groups. We are concerned the relationship between demand and cost-effective.

Figure 2. Factors were related to the EOQ. Source: 10-15.

«Transportation costs are basically defined as constant unit cost. Different cost function reflect better real tariffs where unit costs may grow up or sink with an increase of transported quantity or may change in leaps due to a discrete character of transportation process. Suitable modification of the optimization model allows solving problems with such cost function». [14] Transport cost and economies interact in measuring the calculated optimum distribution production of industry. Low transport cost level is to determine optimization distribution of production concentrations [9].

The ordering costs are the added costs within providing processing an order from a products supplier. The processing is significant link as it has a strong relationship with order, which indicates the cycle time between when the order is obtained and when the product is obtained by the customer. [3]

Inventory costs are the costs related to inventory-taking task. It associated with three types of inventory: process of receive materials, in-process inventory and off-the-shelf items. [15] «Whereas the inventory carrying cost includes taxes, storage, capital, insurance and obsolescence; The cost ordering includes the full expenses of inventory control, order preparation, communication, updating, activities and management supervision».7

Therefore a second hypothesis is offered:

H1: Ordering cost has a strong influence on economic order quantity

H2: Transport cost has a strong influence on economic order quantity

H3: Inventory cost has a strong influence on economic order quantity

These hypotheses can be assumed by applying linear regression analysis. Linear regression is the analytical step for prediction of importance of significance level in hypothesis testing. It is used when we need to predict the scores of a variable based on the scores of another variable. Linear regression analysis is a statistical tool that experiences to investigate relationship between two or more variables from mathematical links. [16, 17, 18, 19]

3. Research finding

Richard B. Chase, Niccolas V Aqualino took attention value of economic order quality and defined different economic order quality for different logistic cost. Their final result of optimal data was calculated (Table1) [20, 21]. According to the data are based on the provided analyses makes it easy to understand the impact of factor analyses and to verify our three hypotheses. Factor analyses or logistical cost for our linear regression were confirmed as independent variable.

Table 1.

Calculations of costs for different order quantity.

|

Economic order quality |

Ordering cost |

Transport cost |

Inventory cost |

|

300 |

540 |

16200 |

338 |

|

380 |

430 |

16340 |

428 |

|

400 |

400 |

16000 |

450 |

|

800 |

200 |

15600 |

898 |

|

1200 |

140 |

16380 |

1346 |

|

1600 |

100 |

14560 |

1782 |

|

1800 |

90 |

14742 |

2005 |

|

2000 |

80 |

14560 |

2228 |

Source [20].

4.1 Performing of Parameter Calculations of linear regression analysis

The list of data from case study Richard B. Chase, Niccolas V Aqualino is used. Our regression analyses depend on how the finding data (Table1) are calculated. The data so collected will be analyzed using statistical method. To test the hypotheses are appropriate when regression analysis is used. We examined, that relations between these factors is strong. The result is presented (Table 2, 3).

Table 2.

Correlation between factors included in the model.

|

|

y |

x1 |

x2 |

x3 |

|

y |

1 |

-0,923 |

-0,85 |

1 |

|

x1 |

-0,923 |

1 |

0.732 |

-0,924 |

|

x2 |

-0,85 |

0,732 |

1 |

-0,848 |

|

x3 |

1 |

-0,924 |

-0,848 |

1 |

Source: author's own.

Relationship between y and x determines parameters of the Standardized coefficient ᵦ (ᵦ > 0 - direct connection, otherwise - reverse). Standardization of the coefficient is done to indicate of which of the independent variables have a greater effect on the dependent variable.

A table 3 show that inventory cost was counted has greater beta and has effect of the dominance factor. Response this hypothesis verifies that Economic Ordering Quantity is greatly dependent on inventory cost. We hypothesize that maximum force will be produced for inventory processing cost.

Table 3.

Linear regression analysis: dependent variable is economical order quality.

|

|

Standardized coefficients |

adjusted R2 |

F |

a |

b |

|

Economic order quality - ordering cost |

-0.92 |

0.85 |

34.57 |

1942.47 |

3.48 |

|

Economic order quality - transport cost |

0,73 |

0.72 |

15.64 |

12287.1 |

0.72 |

|

Economic order quality - inventory cost |

1 |

1 |

0 |

-6.02 |

0.9 |

Source: author's own.

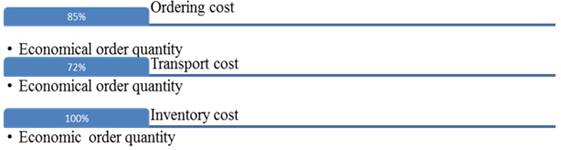

Figure 2 visualizes result of coefficient of determination from three hypothesis. It provides a measure proportion of total variation of outcomes explained by the model. H1 Calculations of linear regression analysis confirms for H1 the R2 was 0,85 indicating that 85 percent of the variation of economic order quality, for H2 the R2 was 0,72 indicating that 72 percent of the variation of economic order quality, for H3 the for the R2 was 1 indicating that 100 percent of the variation of economic order quality. The last result perfectly explains the observed variation.

Inventory cost, ordering cost and transport cost are statistically significant and could be generalized.

Figure 2. Model of research finding. Source: author's own.

4.2. Calculation of the cost function for prediction optimal order quality or logistic cost

Linear regression function is most commonly used for forecasting. The general form of this model: y= a + bx [16, 17, 18,19].

Function explains that order volume increases and reduce expenses in ordering and transporting cost:

1 . The cost functions for 1 factors:

Y = 1922.47-3.48X1 (for prediction optimal order quality)

Y = 506.69-0.24X1 (for prediction optimal logistic cost)

2. The cost functions for 2 factors:

Y = 12287.1-0.72X2 (for prediction optimal order quality)

Y = 16608.56-1X1 (for prediction optimal logistic cost)

Large orders will increase the inventory cost.

3. The cost functions for 3 factors:

Y = -6.02 + 0.9X3 for prediction optimal order quality

Y = 6.7 + 1.11X1 for prediction optimal logistic cost

4. Discussion and recommendation

The review of regression analysis from option data finding Richard B. Chase, Niccolas V Aqualino showed that inventory costs need to be under better control. Many companies have not given serious inventory control in spite of its huge importance. Companies have to focus on modern and available inventory policies. But with the emergence of enterprise storage system appear many problems requiring immediate tasks such as planning, engineering, technology. Modelling and control of current inventory process is probably the most difficult part of control logistical systems. Quality of the organization depends on the correct network model, information trends, improved simulating methods of behavior warehouses processes and cost calculation. These problems are solved by exact mathematical methods in management analyses. It follows that can be solved by vender – managed inventory systems. A description of the models for improvement showed in the science work [22 -31].

Based on the study findings [22, 23], the study illustrates the application of the model and the algorithm from OTL policy (optimized target level). OTL policy is to present a variable target level to be attained wherever a customer is appeared. [22] OTL policy is a mixed integer linear program has improved cash flow and cut its inventory levels. Also the study [24] marked that inventory policies have to focus on several planning aspects. «Including profit maximization in combined inventory management and routing problems, by for example market mechanisms controlling the prices and demand, will be important in future research». [24]. Based on the work study [25] agile inventory control has developed an efficient agile supply chain with regard on consumer-driven process. It organized with all participants of management process are in one place and production facilities close to them. That way insures full flexibility, agility and efficient interprocessor communication. Tightly systems tend to be made simpler and faster collaborate with reduced lead time. Based on the Demand-Driven VMI solution [26] can be displayed full picture of the drivers of market demand. With visibility to future demand availability increased and maintenance costs and operating costs decreased. [26].

Recommendation for inventory control:

- Cross-dock: logistical concepts with impressive practice of joint replenishment. Shipment will be delivered directly without any long-term storage.

- Inventory Holding Costs: this category includes the cost for storage capability. Inventory-holding costs are assumed by average borrowing rate.

- Reduce Order Transaction Costs: the studying role of IT with adaptive structure. Hardware-software complex is to solve problems increased service quality: affect in reducing coordination and operation costs and undiscovered faults [27-30].

Conclusion

The research finding shows that inventory management and according many authorizes (Sople, 2009 4. Craig Voortman, Raja G. Kasilingam) has real strong impact on the effective execution. Implementation of the optimal control in time it means that to ensure stochastic behavior of the material flow and to balance irregularity between material demand and logistics charge. The optimization methods as OTL policy, the correct combination plans, elimination of stages in the supply chain and put into practice strategies accounting for inventory lower of cost suits to solving inventory problems. The objective model minimizes the sum of logistics cost. The cost – optimal model from practical implementation has provided saving logistics operation.

References

1. TIMM GUDEHUS, HERBERT KOTZAB. Comprehensive Logistics. Springer Science & Business Media, 2012 – 933 pages. ISBN: 3642243673, 9783642243677

2. MARTIN STRAKA, DUŠAN MALINDŽAK. Distribučná logistika. Technická univerzita, 2005 – 2008 pages. ISBN: 8080732965, 9788080732967

3. SOPLE. Logistics Management. Pearson Education India, 2007- 359 pages. ISBN: 8131710556, 9788131710555

4. CRAIG VOORTMAN. Global Logistics Management. Juta and Company Ltd, 2004 – 154 pages. ISBN 0702166413, 9780702166419

5. Commercial Development of Regional Ports as Logistics Centers. United Nations. Economic and Social Commission for Asia and the Pacific. United Nations Publications, 2002 – 98 pages. ISBN: 9211201551, 9789211201550

6. RAJA G. KASILINGAM. Logistics and Transportation: Design and Planning. Springer Science & Business Media, 1998-297 pages. ISBN: 0412802902, 9780412802904

7. SATISH C. AILAWADI, P. RAKESH SINGH. Logistics management. PHI Learning Pvt. Ltd., 2011-216 pages. ISBN: 8120345045, 9788120345041

8. REZA ZANJIRANI FARAHANI, NASRIN ASGARI, HODA DAVARZANI. Supply Chain and Logistics in National, International and Governmental Environment: Concepts and Models. Springer Science & Business Media, 2009-334 pages. ISBN: 379082156X, 9783790821567

9. George Norman. Economies of Scale, Transport Costs and Location: Studies in Applied Regional Science Series. Springer Science & Business Media, 1979 - 205 pages. ISBN: 0898380170, 9780898380170

10. DAVID ANDERSON, DENNIS SWEENEY, THOMAS WILLIAMS, JEFFREY CAMM, JAMES COCHRAN. Quantitative Methods for Business. Cengage Learning, 2012-936 pages. ISBN: 1133707599, 9781133707592

11. KEN BOYER, ROHIT VERMA. Operations and Supply Chain Management for the 21st Century. Cengage Learning, 2009-592 pages. ISBN: 0618749330, 9780618749331

12. JOHN A. MUCKSTADT, AMAR SAPRA. Principles of Inventory Management: When You Are Down to Four, Order More

13. JOHN WILEY & SONS. Demand-Driven Inventory Optimization and Replenishment: Creating a More Efficient Supply. John Wiley & Sons, 2013 – 256 pages. ISBN: 1118585712, 9781118585719

14. PETR CENEK, LUDMILA JÁNOŠÍKOVÁ. Models and optimization in transport and logistics. Žilina University publisher, 2008 -186 pages. ISBN: 978-80-8070-951-8

15. JAY RICH, JEFF JONES, MARYANNE MOWEN, DON HANSEN. Cornerstones of Financial Accounting. Cengage Learning, 2013 – 832 pages. ISBN: 1285607155, 9781285607153

16. MARKĚTA KUBÁLKOVÁ. Manažerské výpočty a ekonomická analýza. Nakladatelství C H Beck, 2009-301pages. ISBN: 8074001547, 9788074001543

17. RICHARD HINDLS, STANISLAVA HRONOVÁ, ILJA NOVÁK, EVA JAROŠOVÁ. Grada Publishing, 1999 – 358 pages. ISBN: 8071692557, 9788071692553

18. ALENA SVOZILOVÁ. Zlepšování podnikových procesů. Grada Publishing a.s., 2011- 223 pages. ISBN: 8024739380, 9788024739380

19. Sborník k cyklu prezentací nové generace program. Statistika. Nová generace 6. Praha, 2001 -125 pages. ISBN:80-238-7593-0

20. RICHARD B. CHASE, NICHOLAS J. AQUILANO. Production & Operation Management: A Life Cycle Approach. Irwin, 1992 – 1062 pages. ISBN: 0256128111, 9780256128116

21. DOUGLAS M. LAMBERT, JAMES R. STOCK, LISA M. ELLRAM. Logistika. CP Books, 2005-589 pages. ISBN: 8025105040, 9788025105047

22. LEANDRO C. COELHO, GILBERT LAPORTE. An Optimized Target Level Inventory. Replenishment Policy for Vendor-. Managed Inventory Systems. January 2013. Available online: https://www.cirrelt.ca/DocumentsTravail/CIRRELT-2013-05.pdf.

23. OTL cuts inventory levels by one-third and improves cash flow with system from m-hance. Available online: http://www.m-hance.com/about/news/Overseas-Trading-Limited/.

24. HENRIK ANDERSSONA, ARILD HOFFB, MARIELLE CHRISTIANSENA, GEIR HASLEC. Industrial aspects and literature survey: Combined inventory management and routing. Department of Industrial Economics and Technology Management, Norwegian University of Science and Technology, NO-7491 Trondheim, Norway. Available online: http://www.sciencedirect.com/science/article/pii/S0305054809002962.

25. GALIN ZHELYAZKOV. Agile Supply Chain: Zara's case study analysis. Design, Manufacture & Engineering Management; Strathclyde University Glasgow. Available online: http://galinzhelyazkov.com/wpcontent/uploads/2011/09/AgileSupplyChainZaracasestudyanalysis.pdf.

26. A Demand-Driven Approach to Vendor Managed Inventory. An Oracle White Paper Updated September 2006. Available online:

http://galinzhelyazkov.com/wpcontent/uploads/2011/09/AgileSupplyChainZaracasestudyanalysis.pdf.

27. REZA ZANJIRANI FARAHANI, SHABNAM REZAPOUR, LALEH KARDAR. Logistics Operations and Management: Concepts and Models. Elsevier, 2011 – 469 pages. ISBN: 0123852021, 9780123852021.

28. SUBHRAJIT BOSE. Sustainable 2020: Future Supply Chain through Spyglass. Lulu.com. ISBN: 1105843580, 9781105843587.

29. UPENDRA KACHRU. Production & Operations Management. Excel Books India, 2009 – 810 pages ISBN: 8174465065, 9788174465061.

30. SEAN B. EOM. Inter-organizational Information Systems in the Internet Age. Idea Group Inc (IGI), 2005 – 373 pages. ISBN: 1591403200, 9781591403203.

Поступила в редакцию 04.08.2014 г.